基本情報

出展製品・サービス

Cycloidal Hydraulic Motor

Cycloidal Hydraulic Motor

Main advantages:

High efficiency and energy saving: Compared with traditional hydraulic motors, cycloidal motors have higher efficiency and lower energy consumption.

Low noise: Low noise during operation, suitable for noisy working environment.

Long life: Due to its compact structure and reasonable design, it has a longer service life.

Wide range of application: It can be used in hydraulic drive systems in mechanical automation, aerospace, automobile and other fields.

Application areas:

Mechanical automation equipment (such as conveyors, forging machines, etc.).

Drive elements in hydraulic control systems.

Precision motion control in aerospace equipment.

Main advantages:

High efficiency and energy saving: Compared with traditional hydraulic motors, cycloidal motors have higher efficiency and lower energy consumption.

Low noise: Low noise during operation, suitable for noisy working environment.

Long life: Due to its compact structure and reasonable design, it has a longer service life.

Wide range of application: It can be used in hydraulic drive systems in mechanical automation, aerospace, automobile and other fields.

Application areas:

Mechanical automation equipment (such as conveyors, forging machines, etc.).

Drive elements in hydraulic control systems.

Precision motion control in aerospace equipment.

Hydraulic Winch

Hydraulic Winch

Main features:

High load capacity: hydraulic transmission provides large torque and is suitable for heavy-duty operations.

Precise control: stepless speed regulation, smooth start and stop, and micro-operation.

Strong environmental adaptability: resistant to harsh working conditions such as moisture, dust, and high temperature.

Compact and flexible: the layout of hydraulic components is flexible and suitable for scenes with limited space.

Safe and reliable: multiple braking and overload protection to ensure operation safety.

Main features:

High load capacity: hydraulic transmission provides large torque and is suitable for heavy-duty operations.

Precise control: stepless speed regulation, smooth start and stop, and micro-operation.

Strong environmental adaptability: resistant to harsh working conditions such as moisture, dust, and high temperature.

Compact and flexible: the layout of hydraulic components is flexible and suitable for scenes with limited space.

Safe and reliable: multiple braking and overload protection to ensure operation safety.

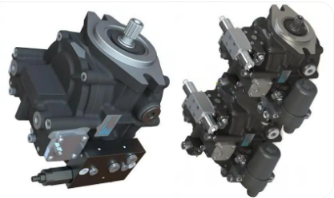

Variable Closed Piston Pump

Variable Closed Piston Pump

Main features:

High efficiency and energy saving: The closed system reduces throttling losses, and the variable function supplies oil on demand, significantly reducing energy consumption.

Precise control: Fast dynamic response, high flow and pressure regulation accuracy, suitable for precision motion control scenarios.

Compact integration: The closed circuit eliminates some pipelines and oil tanks, and the structure is compact, suitable for mobile equipment (such as construction machinery).

High reliability: The plunger pump is resistant to high pressure (up to 40MPa or more), the closed system has low pollution sensitivity and long service life.

Main features:

High efficiency and energy saving: The closed system reduces throttling losses, and the variable function supplies oil on demand, significantly reducing energy consumption.

Precise control: Fast dynamic response, high flow and pressure regulation accuracy, suitable for precision motion control scenarios.

Compact integration: The closed circuit eliminates some pipelines and oil tanks, and the structure is compact, suitable for mobile equipment (such as construction machinery).

High reliability: The plunger pump is resistant to high pressure (up to 40MPa or more), the closed system has low pollution sensitivity and long service life.